- Fiber Laser Cutting Machine

- 8Kw Laser Cutting Machine

- 1Kw Laser Cutting Machine

- 1.5Kw Laser Cutting Machine

- 2Kw Laser Cutting Machine

- 3KW Laser Cutting Machine

- Tube Laser Cutting Machine

- 9M Tube Laser Cutting Machines

- Coil Fed Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- 6Kw Laser Cutting Machine

- 12kw Laser Cutting Machine

- 15Kw Laser Cutting

- Press Braker

Industry 1kw 1.5kw 2kw 3kw 4kw Pipe Fiber Laser Cutting Pneumatic Rotary Chucks Tube Laser Cutter Machine

Basic Info

| Model NO. | GC |

| Structure Type | Gantry Type |

| Laser Classification | Raycus |

| Laser Technology | Laser Control Fault Cutting |

| Type | Fiber Laser Cutting Machine for Plate |

| Transport Package | Stands |

| Specification | / |

| Trademark | HSG |

| Origin | China |

| Production Capacity | 500PCS/Month |

Product Description

HSG Laser Factory Copper Plate Laser Cutting 1500W 2000W 3000W Open Type Sheet Steel CNC Fiber Laser Cutting Machine with Double Drive

Although the power of G3015C fiber laser cutting machine is 1500W-12000w

ApplicationApplicable materials: stainless steel and aluminum of 0.5-8mm, carbon steel of 0.5-16mm, brass of 0.5-6mm, copper of 0.5-4mm, galvanized plates, cold-rolled sheets and more.

Application industry: The G3015C laser cutter is widely used for external processing of metal sheets, home decorations (window grilles, laser-cut screen door), elevators, aerospace components,instruments and more.

.* G3015C is only 4900mm*2250mm, equaling to a large SUV and allows to be put into production in 1 day at the soonest.

* Seven models for selection, positioning accuracy up to ±0.03mm/m, processing format ranging from 3000*1500mm to 8000*2500mm, loading weight of platform 4000kg

Product Parameters

| Machine Parameters | |||||||

| Model | Power | Working Area (L*W) | X/Y-axis Positioning Accuracy | X/Y-axis Repositiong Accuracy | No-load Speed | Loading Weight of Platforms | Overall Dimensios (L*W*H) |

| G3015C III | 1500W-6000W | 3000*1500mm | ±0.03mm/m | ±0.03mm | 140m/min | 700kg | 4900*2250*1700mm |

| G4015C III | 1500W-6000W | 4000*1500mm | ±0.03mm/m | ±0.03mm | 140m/min | 1050kg | 5560*2250*1700mm |

| G4020C III | 1500W-6000W | 4000*2000mm | ±0.03mm/m | ±0.03mm | 140m/min | 1400kg | 6015*3300*1700mm |

| G6015C III | 3000W-6000W | 6000*1500mm | ±0.03mm/m | ±0.03mm | 140m/min | 1500kg | 8300*2800*1700mm |

| G6020C III | 3000W-6000W | 6000*2000mm | ±0.03mm/m | ±0.03mm | 140m/min | 2000kg | 8300*3300*1700mm |

| G6025C III | 3000W-6000W | 6000*2500mm | ±0.03mm/m | ±0.03mm | 120m/min | 2500kg | 8300*3760*1700mm |

| G8025C III | 6000W-12000W | 8000*2500mm | ±0.03mm/m | ±0.03mm | 120m/min | 3200kg | 10500*3600*1700mm |

| G6025C III-H | 6000W-12000W | 6000*2500mm | ±0.03mm/m | ±0.03mm | 100m/min | 4700kg | 8600*3800*1700mm |

| G8025C III-H | 6000W-12000W | 8000*2500mm | ±0.03mm/m | ±0.03mm | 100m/min | 6300kg | 11000*3800*1700mm |

| G12025C III-H | 6000W-12000W | 12000*2500mm | ±0.03mm/m | ±0.03mm | 100m/min | 3200kg | 15300*3800*1700mm |

Detailed Photos

Ipg Raycus Max CNC desktop Fiber Laser Cutting Machine for Carbon Stainless Steel Sheet Aluminum with 1500 watt 2000/3000/6000W/12000W Laser Cutter Metal

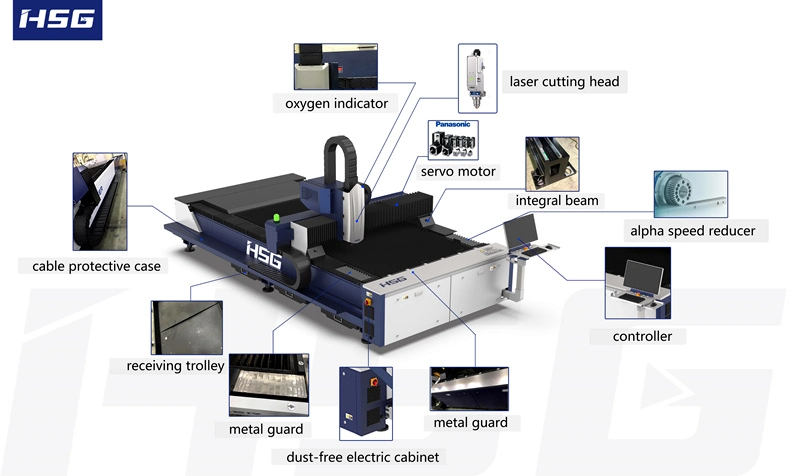

1. Core ComponentsIts dual servo motors can run at rotating speed of up to 3750r/min.

We import speed reducer and gear wheels from German WITTENSTEIN alpha.

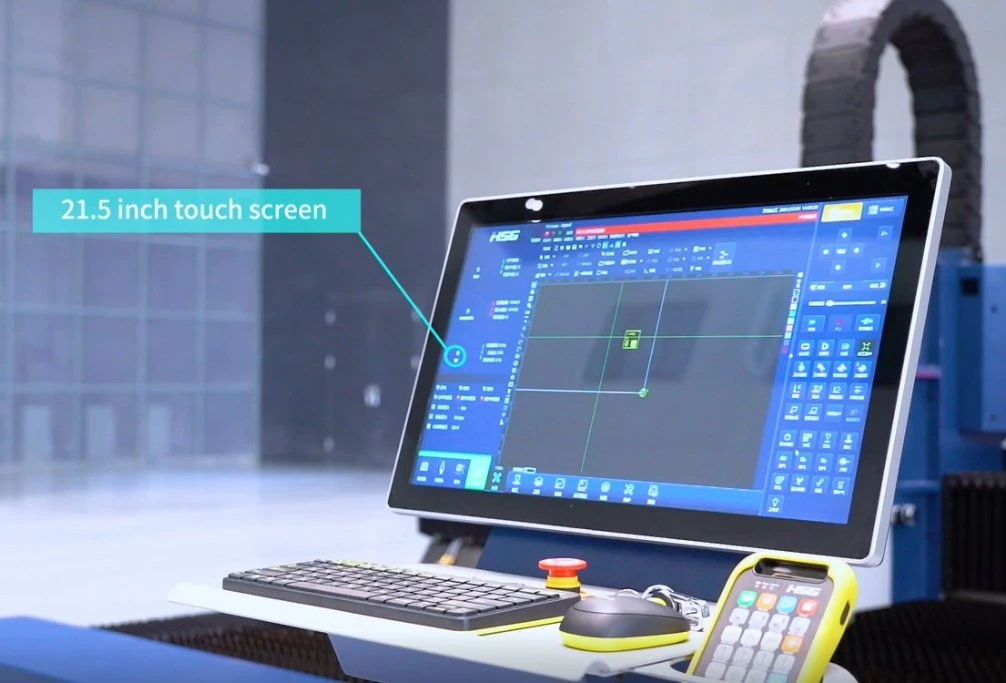

2. Alpha T Bus CNC System

Alpha T can make data transmission via a network cable.

Easy to operate even by green hands

Match with 2000+ process data on its graphical programming interface

Compatible with multiple files, incl. DXF, DWG, PLT and NC code

Micro-connection cutting

Active obstacle avoidance

Real-time monitoring of core components

Active reminder of machine maintenance

HSG-NEST nesting software

* Bus refers to data transmission mode via on-site bus control system.3. Autofocus Cutting Head* Autofocus accuracy ±0.01mm

* Self water-cooling mode

* Take control of gas flow to enable mirror-like surface cutting

* Feel surroundings and lift itself up to avoid obstacle

* Anti-pollution design

4. Extruded Aluminum Beam

The aluminum alloy is adopted. Our beam is designed as honeycomb anti-compression structure and made by using extrusion molding process.

5. Carbon Steel Welded Machine Bed

* 20 years using without deformation

* High-quality carbon steel adopted, with less impurity, less heat absorption and good rigidity

6. GC III performs well in sheet cutting quality and we will carefully check the entire machine and all components before delivery to you. It is popular globally and has been highly praised by purchasers since its first launch to market.

Cutting Sample

* Customizable size: 4m×2m, 6m×2m, 8m×2m.

** We offer lasers in a variety of powers. The material and thickness levels to be cut directly depend on the laser power.

Company Profile

HSG Laser, founded in 2006 as a hi-tech enterprise focusing on R&D, production and sales of laser equipment, is dedicated to serve global customers with intelligent metal forming solutions.

RFQ

Q1:what kind of machine I should choose?

Very easy to choose. Just tell us what you want to do by using CNC laser machine, then let us give you perfect solutions and suggestions.

Q2: When I got this machine, but I don't know how to use it. What should I do?

We will send video and English manual with the machine. If you still have some doubts, we can talk by telephone or skype and e-mail.

If necessary, our engineers can make on-site debugging, trianing and maintenance.

Q3: Before sending me an inquiry on our fiber laser, it is better for you to provide me the following information

1)Your metal or non-metal material size. Because in our factory, we have different models according to working area.

2)Your materials. Metal/ Steel/ Aluminum/ Copper/ Iron/ Carbon Steel/ Brass/ Stainless Steel/ Galvanized Iron/Bronze Plate, etc

3)Maximum cutting thickness. Different laser power with different cutting ability.