- Fiber Laser Cutting Machine

- 8Kw Laser Cutting Machine

- 1Kw Laser Cutting Machine

- 1.5Kw Laser Cutting Machine

- 2Kw Laser Cutting Machine

- 3KW Laser Cutting Machine

- Tube Laser Cutting Machine

- 9M Tube Laser Cutting Machines

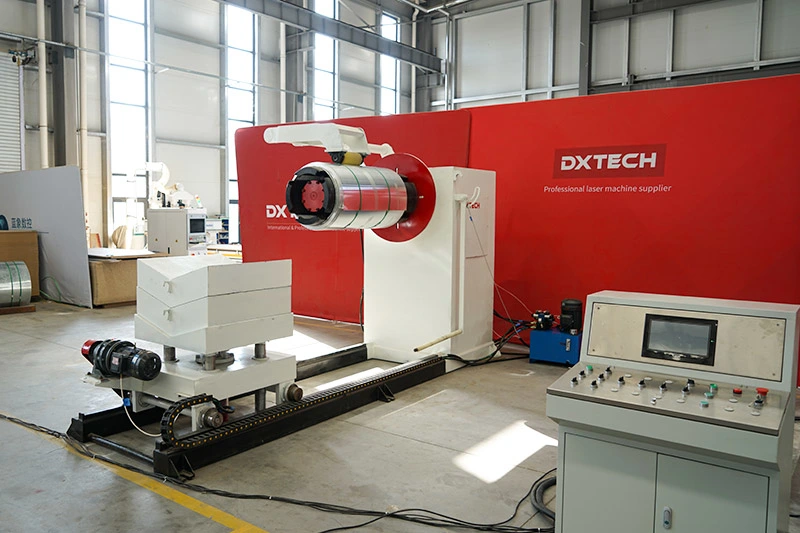

- Coil Fed Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- 6Kw Laser Cutting Machine

- 12kw Laser Cutting Machine

- 15Kw Laser Cutting

- Press Braker

Dxtech Metal Coil Auto Fed Fiber Laser Cutting Machine Production

Basic Info

| After-sales Service | 24-Hour Online Service |

| Warranty | 2-Year |

| Application | Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry |

| Cooling System | Water Cooling |

| Technical Class | Continuous Wave Laser |

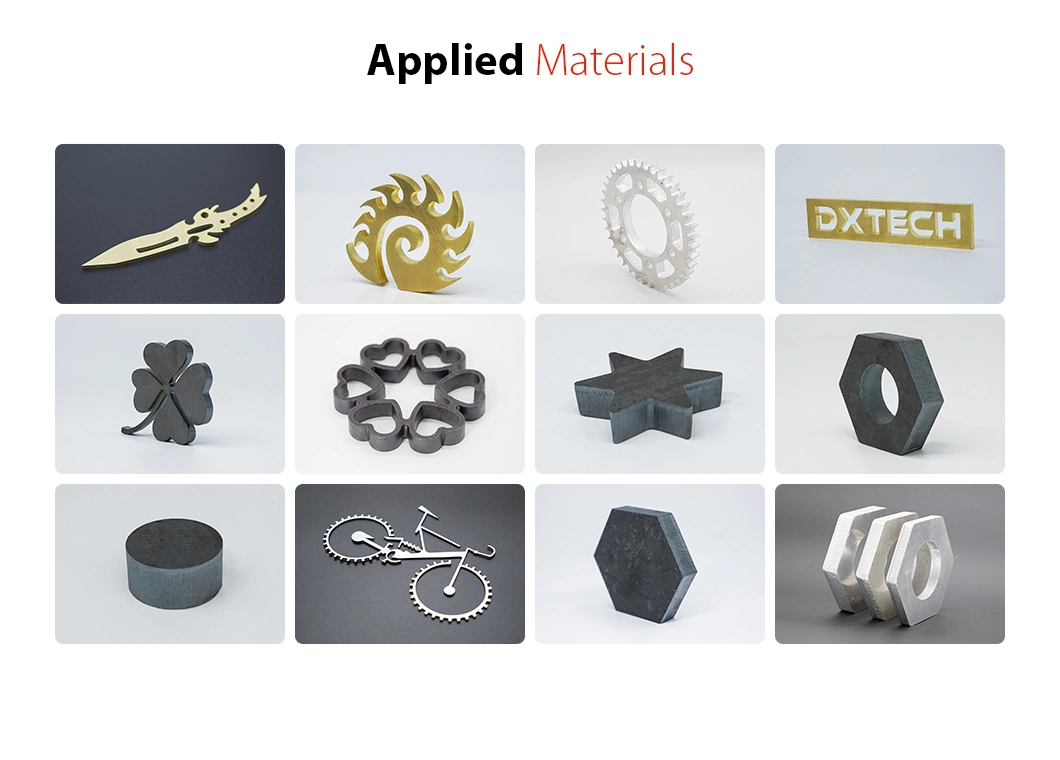

| Applicable Material | Metal |

| Structure Type | Gantry Type |

| Laser Classification | Free Electron Laser |

| Laser Technology | Laser Control Fault Cutting |

| Cutting Materials | Stainless Steel Carbon Steel etc( Metal Laser Cutt |

| Laser Power | 1000W/2000W/3000W/4000W |

| Model | 1530 1560 2060 |

| Laser Source | Raycus/Ipg |

| Motor | Japan Yaskawa |

| Cast Iron Bed | Gray Cast Iron |

| Driving System | FUJI Servo Motor |

| Transmission | Hiwin Guide Rails |

| Table Type | Blade Table |

| Certification | CE/ISO/SGS |

| Accuracy | 0.02mm |

| Cast Aluminum Beam | Higher Machining Accuracy |

| Component | Fiber Laser, Stepper Motor, Servo Motor, Bed, Lase |

| After-Sales Service Provided | Free Spare Parts |

| Transport Package | 3 Layers |

| Specification | 5000 kg |

| Trademark | DXTECH |

| Origin | Jinan, Shandong Province |

| HS Code | 8461500090 |

Product Description

1. The loading material weight can reach 20T, breaking through the feeding limit of ordinary 3T, which is 6 times the efficiency of ordinary feeding equipment.

2. Stronger stress relief: after the coil is uncoiled, the sheet metal is leveled by the leveling machine, and the stress of the sheet material during the leveling process is eliminated. So the sheet material is flatter and a better cutting experience is obtained.

3. High-precision transmission structure: using ultra-precision transmission system, the transmission accuracy of sheet metal is about ±0.5MM, which can ensure higher accuracy.

4. Fully automatic assembly line: from feeding - uncoiling - leveling - cutting - unloading, the whole process is automated, which can achieve zero waste of coil material and improve the utilization efficiency of sheet materials.

5. Flexibility: this coil production line breaks through the limit of the ordinary laser cutting length, and has subversive significance in some fields.

| Model | DXTECH-1530SC | DXTECH-1540SC | DXTECH-1545SC |

| Total machine weight | 6.2t | 6.7t | 6.9t |

| Worktable | Rolling blade | Rolling blade | Rolling blade |

| Positioning accuracy | ±0.05mm | ±0.05mm | ±0.05mm |

| Repositioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

| Max. acceleration | 1.5G | 1.5G | 1.5G |

| Laser power | 1kW - 2kW | 1kW - 2kW | 1kW - 2kW |

| Max. running speed | 140m/min | 140m/min | 140m/min |

| Leveling speed | ≤20m/min | ≤20m/min | ≤20m/min |

| Coil weight | ≤10t | ≤10t | ≤10t |

--Materials. Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum-plating zinc plate, copper, and other metals.

--Various industry. The fiber laser cutting machine is widely used in automative industry, advertising industry, kitchenware industry, sheet metal industry, cabinet industry, fitness industry etc. Professional in many manufacturing and processing industries like sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, grain machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising , metal processing, kitchen processing and other industries.