- Fiber Laser Cutting Machine

- 8Kw Laser Cutting Machine

- 1Kw Laser Cutting Machine

- 1.5Kw Laser Cutting Machine

- 2Kw Laser Cutting Machine

- 3KW Laser Cutting Machine

- Tube Laser Cutting Machine

- 9M Tube Laser Cutting Machines

- Coil Fed Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- 6Kw Laser Cutting Machine

- 12kw Laser Cutting Machine

- 15Kw Laser Cutting

- Press Braker

3m/6m/9m/12m Metal Pipe Tube Fiber Laser Cutting Machine with Automatic Loading

Basic Info

| Model NO. | LT-6020 |

| Laser Technology | Fiber Laser |

| Laser Source | Ipg, Raycus, Max |

| Laser Head | Germany Precitec, Switzerland Raytools |

| Control System | Cypcut, Fuscut, Beckhoff |

| Driving System and Motor | Yaskawa, Japana |

| Guide Rail | PMI, Taiwan |

| Gear | Yyc, Taiwan |

| Minimum Cutting Width | 0.02-0.08 mm |

| Available Cut Pipe Shape | Round, Circular, Rectangular, Oval, etc. |

| Cutting Length | 200-20000 mm |

| Certification | Ce, FDA, SGS |

| Electrical Part | France Schneider |

| Pneumatical Part | Japan SMC |

| Reducer | Japan Shimpo |

| Machine Bed | Heavy Duty |

| Chucks | Pneumatic or Hydraulic Chuck |

| Transport Package | 40 Foot Container |

| Specification | 6000x2000; 12000x2000, Customization |

| Trademark | ACME |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 720 Sets/Year |

Product Description

3m/6m/9m/12m Metal Pipe Tube Fiber Laser Cutting Machine with Automatic Loading

(Exclusive Supplier)

ACME Pipe Tube Laser Cutting Machine LT-6020 is designed for high precision fasttube processing. It provides efficient processing of Round, Rectangular, Square, Oval, Triangle, D shape and other shapes of metal tube. Even Angle steel and Channel steel also can be cut at optimal speed using a fiber laser. The integration of leading-brand components assures you of top performance and high reliability. It has all functions as a professional CNC laser pipe tube cutting machine but with economic price.

CUTTING SAMPLESPRODUCT FEATURE

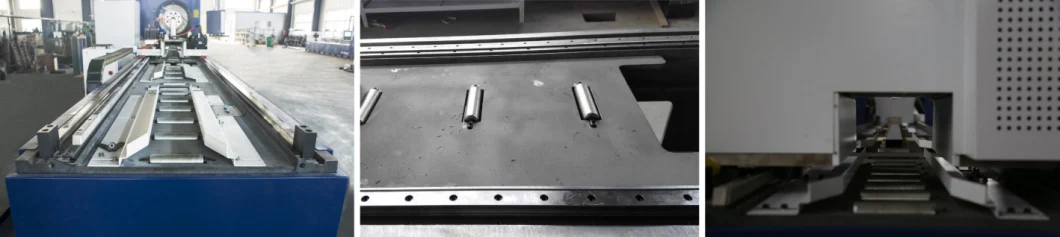

Heavy duty 18-25mm thickness machine bed.Made from whole high strength steel panel.With heat and aging treatment.Milled by Italy COLGAR machining center with high precision.

Large Diameter Self-Centering Pneumatic Chucks for both front and back.

Automatic centering pneumatic high-speed safety chuck.

Patent design15s automatic feeding efficient system.

This patent makes it happen that loading tubes when the machine is still working.The operator can load the tubes while the machine is cutting other tubes.It reduces time cost and human cost a lot, and increase production efficiency.

We introduced US Hass, Japan Mazak and Taiwan Yingyuan.ACME has established our own High-Precision CNC Machining Center.Together with Italy COLGAR large gantry milling machine. All the core components of the machines are manufactured at a high accuracy.

TECHNICAL PARAMETER

| No. | Item | LT-6020 | |

| 1 | Control System | Cypcut / Fuscut | |

| 2 | Laser Source Power | Germany IPG/China Raycus / China MAX | |

| 3 | Laser Head | Germany Precitec/Switzerland Raytools | |

| 4 | Water Chiller | Tongfei / Hanli | |

| 5 | Servo Motor | Japan Yaskawa | |

| 6 | Mahine body(bed) | Heavy DutyEnclosed or Open type | |

| 7 | Chuck | Type | Both Automatic Self-CenteringPneumatic or Hydraulic Chucks |

| Diameter (mm) | φ20-φ600 | ||

| Min. Waste Length (mm) | 200 | ||

| Rated Resolution (r/min) | 40 | ||

| Max. Resolution (r/min) | 130 | ||

| Weight Bearable (together) | 500kg/customized | ||

| 8 | Rail Width | X-25mm, Y-35mm | |

| 9 | Transmission | X-axis: Ball ScrewY-Axis: RackZ-axis: Ball Screw | |

| 10 | Reducer | Japan Shimpo | |

| 11 | Positionning Accuracy | ±0.03/1000mm | |

| 12 | Repeat Positionning Accuracy | ±0.015 | |

| 13 | Electrical Part | France Schneider | |

| 14 | Pneumatic Part | Japan SMC | |

| 15 | Dust Extraction System | Air Fan | |

| 16 | Tube Support | Large Variable-Diameter Wheel | |

| 17 | Loading | Automatic Loading from Back or Side | |

CERTIFICATION & PATENTS

PACKAGE & SHIPPING

AFTERSALES SERVICE

1. OEM&ODM services. 2. Two or Thrree years guarantee time. 3. Life-long free technical support. 4. Consumable parts continuous supply. 5. English Speaking Engineers available to overseas services. 6. Free Training on machine installation, commissioning, operation, maintenance, etc.

CUSTOMERS SHOW

BRAND STORY

With industry-leading technology and continuous R&D capability, Jinan ACME has provided customers with the highest cost-effective laser equipment.Fiber laser cutting machine is our core products. All the core components are independently designed and manufactured with high precision.With the confidence given from years of experience in machine manufacturing sector, we have exported the machines to all around the world with a perfect understanding of customer satisfaction and giving a continuous contribution to the national economy.

Why Choose Fiber Laser?

More companies than ever before are investing in fiber lasers. While the automotive industry was undoubtedly the early adopter, this relatively new solution is being snapped up across the board and when you consider the advantages, it's easy to see why. EXTRA SPEED

The sheer speed of fiber laser markers makes them the first choice for customers looking to increase efficiency. They're the fastest laser marking technology at their wavelength, delivering marking times of less than one second for some applications. While older, more established laser technology is available-including diode-pumped solid-state (DPSS) lasers, lamp-pumped lasers, and carbon dioxide (CO2) lasers-none can beat a fiber laser for combined mark speed and quality.

This means fiber lasers can break new ground. For example, one of Laser Lines' customers is an automotive component manufacturer that needs to mark serial codes exceptionally fast-in under half a second-which wouldn't be possible with any other type of laser.

ENERGY EFFECIENCY

Despite being faster, fiber lasers are energy-efficient compared to the alternatives. Not only does this result in reduced power consumption, but it also helps make the system simpler, smaller, and more reliable.

Fiber laser technology uses basic air cooling rather than an additional chiller unit, which would be costly and cumbersome. With many businesses finding both cash and floor space in short supply, compact and efficient fiber laser marking solutions are proving to be the right fit.

LONG LIFE

The life expectancy of a fiber laser far exceeds that of other laser solutions. In fact, the diode module in a fiber laser typically last three times longer than other technologies. Most lasers have a life of around 30,000 hours, which typically equates to about 15 years' use.

Fiber lasers have an expected life of around 100,000 hours, which means about 45 years' use. Saying that, will companies still be using the same fiber laser in 45 years? I doubt it! Regardless, this option does deliver an impressive return on investment.

FAQ

Why should I choose ACME Laser ?

- We have been manufacturer for 11 years.

- We offer maintenance-free and technology support.

- Most of our products have CE,SGS,FDA,FCC certifications.

- Our products have quality warranty.

- We have own research room ,workshop and design team.

- ACME LASER has been exporting to more than 32 countries around the world.

This is first time buying this machine,how to use it?

- We have free training for1-2 days.It is easy to learn.

- The best way is that we offer prefessional engineer to taech you face to face.

- If you couldn't come to our company, we will give you menu and video, our engineer teach you online.

How to maintain the machine?

- The environment needs be clear.

- The temperture can not be high.

- Our guide needs lubricating oil for 2-3 drops about.

If I have some problems ,what should I do ?

- You can contact our salesman directly ,our engineer will check the problem.

- During the warranty, maintainance is free.

- Although over the warranty,we also offer life-long technology support in free.