Category

- Fiber Laser Cutting Machine

- 8Kw Laser Cutting Machine

- 1Kw Laser Cutting Machine

- 1.5Kw Laser Cutting Machine

- 2Kw Laser Cutting Machine

- 3KW Laser Cutting Machine

- Tube Laser Cutting Machine

- 9M Tube Laser Cutting Machines

- Coil Fed Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- 6Kw Laser Cutting Machine

- 12kw Laser Cutting Machine

- 15Kw Laser Cutting

- Press Braker

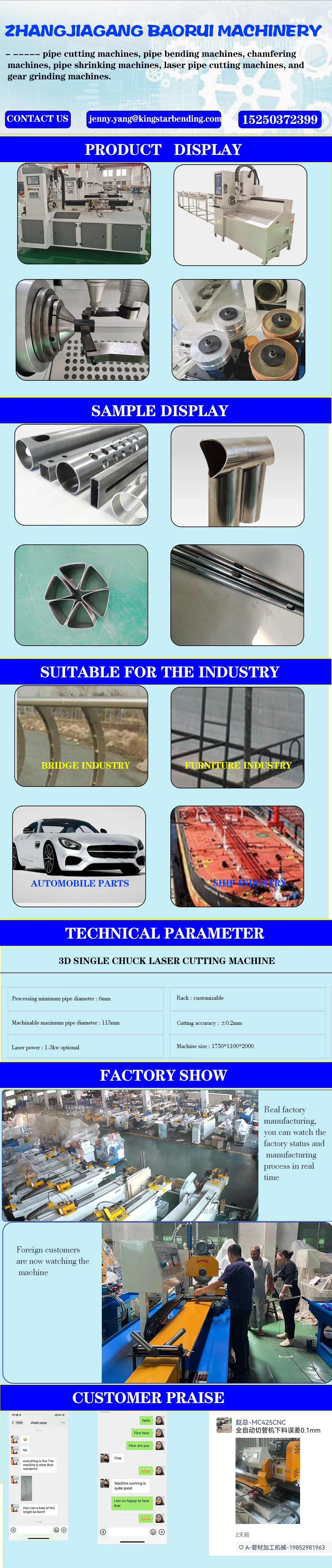

Br1000W CO2 Fiber Laser Pipe Tube Cutting Machine 3D Laser Cutting Machine

Package size per unit product 2000.00cm * 1000.00cm * 600.00cm Gross weight per unit product 5000.000kg Our company is a

Basic Info

| Model NO. | BR1000W |

| After-sales Service | on Line |

| Warranty | Yes |

| Application | Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Automotive Industry, Advertising Industry |

| Cooling System | Air Cooling |

| Technical Class | Pulse Laser |

| Applicable Material | Metal |

| Structure Type | Gantry Type |

| Laser Classification | Fluid Laser |

| Laser Technology | Laser Flame Cutting |

| Feature | Automated Loading |

| Configuration | 6-Axis |

| Video Outgoing-Inspection | Provided |

| Transport Package | Wooden Case |

| Specification | 1000W |

| Trademark | Baorui |

| Origin | China |

| Production Capacity | 500PCC/Year |

Packaging & Delivery

Package size per unit product 2000.00cm * 1000.00cm * 600.00cm Gross weight per unit product 5000.000kgProduct Description