- Fiber Laser Cutting Machine

- 8Kw Laser Cutting Machine

- 1Kw Laser Cutting Machine

- 1.5Kw Laser Cutting Machine

- 2Kw Laser Cutting Machine

- 3KW Laser Cutting Machine

- Tube Laser Cutting Machine

- 9M Tube Laser Cutting Machines

- Coil Fed Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- 6Kw Laser Cutting Machine

- 12kw Laser Cutting Machine

- 15Kw Laser Cutting

- Press Braker

Perfect Fully Cover 6kw Laser Cutting Machine Size 1500mm*3000mm

Basic Info

| Application | Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Advertising Industry |

| Cooling System | Water Cooling |

| Technical Class | Continuous Wave Laser |

| Applicable Material | Metal |

| Machine Body | Qiaolian |

| Fiber Laser | Max Brand |

| Controller | Hypcut8000 Ethercat Bus System |

| Automatic Height Controller | Blt641/661 |

| Motor and Driver | Japan Yaskawa |

| Precision Reducer | Japan Shimpo/3 Arc-Min |

| Linear Guide | German Rexroth/INA |

| Rack | Taiwan Yyc |

| Pressure Monitoring Alarm Device | SMC |

| Proportional Valve | Aventics |

| Electronic Pieces | France Schneider |

| Voltage Stabilizer | Shanghai Huadong |

| Transport Package | Tray |

| Specification | 6000-2000MM |

| Trademark | QIAOLIAN |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 2000sets Per Year |

Product Description

Perfect fully cover 6kw laser cutting machine size 1500mm*3000mm

I.Features

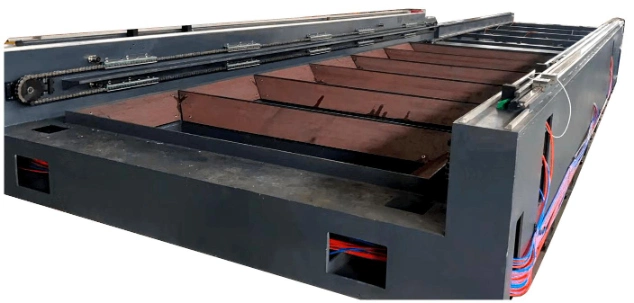

1.Double Table ,Save time for loading and unloading materials.

2.The cutting area is protected by a cover to prevent splashes and be safe

3.With a camera, the cutting situation is clear at a glance.

II. Advantages

1.Steel Plate Welding Bed

1.Our laser cutter body is welded by plate. After welding, the stress is removed by one-time quenching. After natural cooling, the rough machining is performed, then the stress is removed by two-time quenching, and after natural cooling, the finishing is performed. The equipment within 13m is integral type, and the upper gantry milling machine is processed once.Body advantage: it is more strong and stable. Using long time, it is also have high accuracy and ensure cutting accuracy. 2.Process dust extraction experts, ship-type box design, partitioned dust extraction, more concentrated and reasonable air ducts, and better dust extraction effect; 3.Three exchange table modes: parallel exchange (standard), mechanical lift exchange, hydraulic exchange, to meet the different preferences and needs of global users, to meet the personalized customization.

2. Cast Aluminum Beam

Adopts aluminum cast beam, light weight, good dynamic response, faster acceleration and better comprehensive cutting effect;

3. High-end Intelligent EtherCAT Bus System

*Provide fine cutting technique, smooth start and end in the toolpath cutting.

*Support intelligent barrier avoidance, laser head frog-leap lifting in production.

*Support scan QR import drawing, task scheduling, and multi-area production etc.

*Maximum acceleration 1.5G.

*Provide dual-Y drive position error detect function.

4.Intelligent bus control cutting head, Active Collision Prevention

It can adjust focal point by itself according to material thickness and apply to multiple focal lengths, reducing punching duration and improving punching quality, moreover, which will perceive the surroundings and lift up to avoid obstacles intelligently;Flying cutting micro-connection, preventing sheet upwarp and realizing high speed and high stability while cutting.

5.Imported Parts, Precision Guaranteed

| Equipped with dualhigh-powered servo motors and drivers which from German | Core transmission parts like speed reducer and gears are imported from Japan | High-precision racks,guide rails and ball screws are produced by world-famous brands. |

6. Quality Control System

Rigorous quality inspection of the assembly process, perfect quality system, high-precision inspection and inspection equipment: laser interferometer, laser collimator and three-coordinate projector, to ensure that each delivered customer equipment can meet the company's factory quality standards;III. Parameters

| Model | JLMD3015 | JLMD4020 | JLMD6020 | JLMD6023 | JLMD8025 | JLMD10025 | JLMD12025 | JLMD12030 |

| Power | 6000W | |||||||

| Working Area (L*W) | 3000*1500mm | 4000*2000mm | 6000*2000mm | 6000*2300mm | 8000*2500mm | 10000*2500mm | 12000*2500mm | 12000*3000mm |

| X/Y-axis Positioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm |

| Positioning speed | 150m/min | 150m/min | 150m/min | 150m/min | 150m/min | 150m/min | 150m/min | 150m/min |

| Max. Acceleration | 2G | 2G | 2G | 2G | 2G | 2G | 2G | 2G |

*The above data are for reference only, subject to the actual product!IV. Customers

V. Cutting samples