- Fiber Laser Cutting Machine

- 8Kw Laser Cutting Machine

- 1Kw Laser Cutting Machine

- 1.5Kw Laser Cutting Machine

- 2Kw Laser Cutting Machine

- 3KW Laser Cutting Machine

- Tube Laser Cutting Machine

- 9M Tube Laser Cutting Machines

- Coil Fed Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- 6Kw Laser Cutting Machine

- 12kw Laser Cutting Machine

- 15Kw Laser Cutting

- Press Braker

Linghein Energy-Saving Lsc Series Screw Air Compressor for Laser Cutting

Basic Info

| Model NO. | LSC |

| Type | Twin Screw Compressor |

| Drive Mode | Belt Drive |

| Air-End | Atlas-Copco Group |

| Original | China |

| Net Weight | 360 |

| Dimension(L*W*H) | 740*850*1030 |

| HS Code | 8414804990 |

| Production Capacity | 5000unit/Month |

Product Description

1.Atals-Copco Air-End

Atlas-Copco Group 149years air-end research & development experience.

High technology content air-end,average 8~10% energy saving compare with Chinese air end.

Atals-copco design gear box,reliability & durable

2.High Efficiency & Save Energy

High efficiency & energy saving intake valve,keep in lower unloading pressure and avoid large energy consumption when unloading.

New oil tank design,lower pressure drop and less energy consumption.

Shortest piping system in order to reduce the pressure drop.

3.Easy Installation & Operation

Compressor is filled with inbrication oil before delivering. You can operate it after installing and power on.

PLC intelligent control system, has the remind & record function, show the compressor situation clearly.

4.Low noise & low vibration

Atlas-copco air-end, low noise & vibration.

Aseismatic design.

Motor with noise reduction baffle.

5.Reliability & Safety

Reliability bigger cooler, lower operating temperature.

Safety and reliability filter system.

Integrated fan, stable and high efficiency.

| Model | MaxWorking Pressure | CAPACITY(F.A.D) | Motor Power | Net Weight | Transmission | Noise | Connection | Dimension(Lx W x H) | Remark | ||

| -- | bar | psig | m3/min | hp | kw | kgs | DB(A) | inch | mm | -- | |

| LSC11 | 16 | 232 | 0.95 | 15 | 11 | 350 | Belt Drive | 65±2 | G3/4'' | 740*850*1030 | |

| LSC11TMDD | 16 | 232 | 0.95 | 15 | 11 | 600 | Belt Drive | 65±2 | G1/2'' | 1490*950*1600 | with 1pc dryer + 3 pcs filters+1 pc 240L receiver tank |

| LSC15 | 16 | 232 | 1.3 | 20 | 15 | 360 | Belt Drive | 65±2 | G3/4'' | 740*850*1030 | |

| LSC15TMDD | 16 | 232 | 1.3 | 20 | 15 | 600 | Belt Drive | 65±2 | G1/2'' | 1490*950*1600 | with 1pc dryer + 3 pcs filters+1 pc 240L receiver tank |

| LSC18.5 | 16 | 232 | 1.7 | 25 | 18.5 | 400 | Belt Drive | 69±2 | G1'' | 740*850*1300 | |

| LSC18.5TMDD | 16 | 232 | 1.75 | 25 | 18.5 | 800 | Belt Drive | 67±2 | G1'' | 1460*980*1770 | with 1pc dryer + 3 pcs filters+2 pc 300L receiver tank |

| LSC22 | 16 | 232 | 2.1 | 30 | 22 | 410 | Belt Drive | 69±2 | G1'' | 740*850*1300 | |

| LSC22TMDD | 16 | 232 | 2.1 | 30 | 22 | 800 | Belt Drive | 67±2 | G1'' | 1460*980*1770 | with 1pc dryer + 3 pcs filters+2 pcs 300L receiver tank |

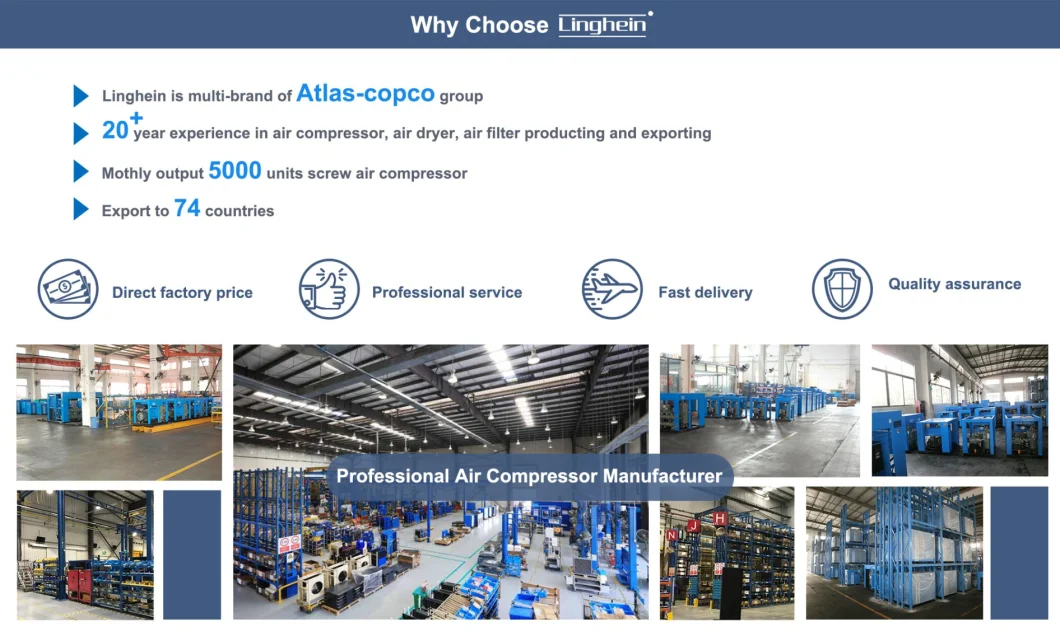

Q1: Are you a manufacturer or trading company?

A1: Linghein is professional screw air compressor factory located in Wuxi, China, Olymtech is Linghein overseas market sales representative.

Q2: Linghein is real member of Atlas-copco group?

A2: Yes, in 2010, Sweden Atlas-copco 100% acquired Linghein.

Q3: Linghein air-end from Atlas-copco?

A3: Yes, Linghein LS/LSV, LOH, LSH and CS series air compressors all use Atlas Copco's air-end.

Q4: What's your delivery time?

A4: about 10-20days after you confirm the order, other voltage pls contact with us.

Q5: How long is your air compressor warranty?

A5: One year for the whole machine since leave our factory.

Q6: What's the payment term?

A6:We accept T/T, LC at sight, Paypal etc.

Also we accept USD, RMB, JPY, EUR, HKD, GBP, CHF, KRW.

Q7: What's the Min. Order requirement?

A7: 1unit

Q8: What service you can support?

A8: We offer after-sales service, custom service, production view service and one-stop service.