- Fiber Laser Cutting Machine

- 8Kw Laser Cutting Machine

- 1Kw Laser Cutting Machine

- 1.5Kw Laser Cutting Machine

- 2Kw Laser Cutting Machine

- 3KW Laser Cutting Machine

- Tube Laser Cutting Machine

- 9M Tube Laser Cutting Machines

- Coil Fed Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- 6Kw Laser Cutting Machine

- 12kw Laser Cutting Machine

- 15Kw Laser Cutting

- Press Braker

Electro-Hydraulic Servo 6+1 CNC Bending Machine Press Brake

Basic Info

| Model NO. | WE67K |

| Certification | ISO 9001:2000, ISO 9001:2008, CE |

| Automation | Semi-Automatic |

| Suitable for | Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel |

| Type | Hydraulic Bending Machine |

| Color | Optional |

| Timely Delivery | About 15 to 20 Days |

| Control System | Delem |

| Key Selling Points | High-Accuracy |

| Color&Logo | Customized |

| Voltage | as Customer Requirement |

| Transport Package | Wooden Cases |

| Specification | 70T/1600 |

| Trademark | LXSHOW |

| Origin | China |

| HS Code | 8462219000 |

| Production Capacity | 3000 Sets/Year |

Packaging & Delivery

Package size per unit product 290.00cm * 190.00cm * 245.00cm Gross weight per unit product 4000.000kgProduct Description

Product Description

Electro-hydraulic Servo 6+1 CNC Bending Machine Hydraulic Press Brake

The frame is composed of oil tank, bracket, workbench, left and right wall panel and slide block, which ensures the structural strength of the frame. After welding, it is processed on the large floor boring and milling machine after stress removal. In particular, the slide block adopts vertical processing technology (because the working state of the slider is vertical) so as to ensure the straightness of the upper die mounting surface of the slider in the working state.

The machine has higher labor productivity and higher accuracy of bending metal plate, using different shapes of the upper and lower mold, can be bent into various shapes of the workpiece, the slider stroke can be a sheet material for a bending forming, after multiple bending can be obtained more complex shape of the workpiece, when equipped with the corresponding equipment, can also be used for punching.

Product Parameters

Main Technical Parameters| Machine model | WE67K-70T/2000 | |

| Nominal Pressure | 700 kN | |

| Bending length | 2000mm | |

| Distance between columns | 1490 mm | |

| Throat Depth | 230 mm | |

| MAX Pressure of system | 22Mpa | |

| Slide running condition | Moving Journey/stroke | 200mm |

| fast down speed | 180mm/s | |

| return speed | 110mm/s | |

| working speed | 10mm/s | |

| Slide running precision | Position accuracy | ±0.03mm |

| Repeat Position accuracy | ±0.02mm | |

| Main motor power | Power | 5.5 KW |

| rotate speed | 1440r/min | |

| Operate system | Model | DE15 System |

| Oil Pump | Model | USA sunny |

| Bending precision | angle | ±30' |

| straightness | ±0.7mm/m | |

| Voltage | 220/380/420/660 V | |

| Tech Info | 1)Tonnage=8*1.68*stainless Steel thickness*plate Width2)Tonnage=8*carbon steel plate thickness*plate width | |

Product Details

Control System:Delem DA66T1 2D touch graphic programming

2 3D product graphic simulation display3 Complete Windows application package4

Compatible with Delem modular structure system

Product Shape Structure

1 Use UG (finite element) analysis method, computer aided optimization design, beautiful appearance.

2 The machine adopts steel plate welding structure, with enough strength and stiffness, hydraulic transmission to ensure that the work will not cause serious overload accident due to the change of plate thickness or the improper selection of the die "V" groove. In addition, the machine has the characteristics of stable work, easy operation, low noise, safe and reliable.

Hydraulic System

1 Adopt the most advanced full closed-loop electro-hydraulic servo synchronous control system;

2 Hydraulic system complete set imported from Germany ARGO Company;

3 The sealing parts in the cylinder are international famous brands with strong sealing and long service life.

4 The hydraulic system has overload overflow safety protection;

5 Oil pump high pressure filter blocking alarm;

6 Clear and intuitive display of oil level height;

Table Deflection Compensation System

1 The compensation system is the control of the table to add convex numerical control shaft, can obtain accurate deflection compensation on the full length of the table.

2 The deflection compensation table can be maintenance-free during the life of the machine tool. Compared with the compensation method of hydraulic cylinder, it has incomparable advantages.

3 Can form effective "reverse complement" at both ends of the compensation curve

Electrical Control System1 Electrical components imported from abroad or joint venture products, in line with international standards, safe and reliable, long life, anti-interference ability

Strong force;

2 Movable button station (including foot switch), convenient operation, emergency stop function;

3 The working system should have the necessary limit protection measures, once abnormal should be able to detect through the system and immediately alarm;

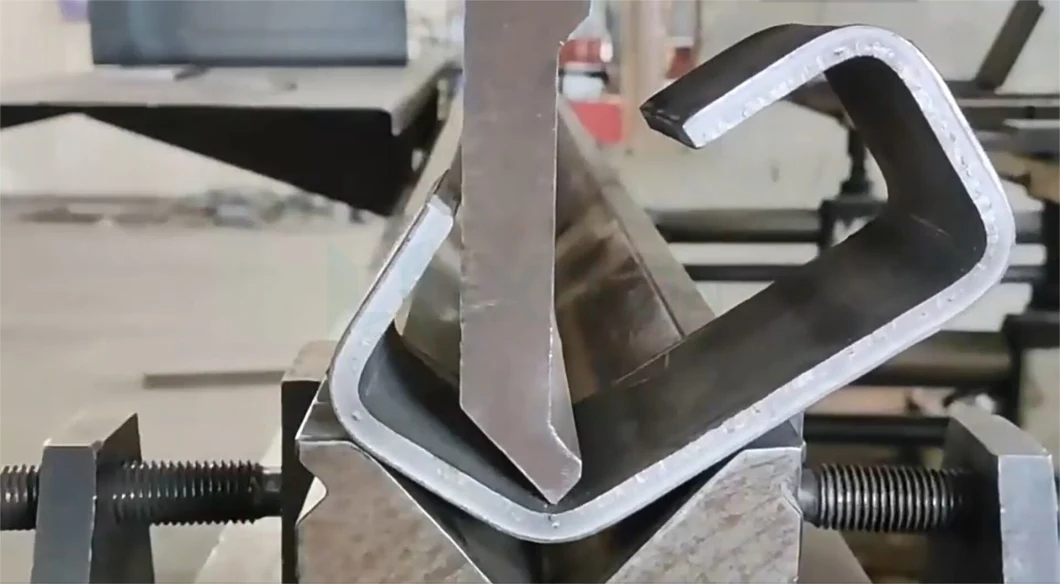

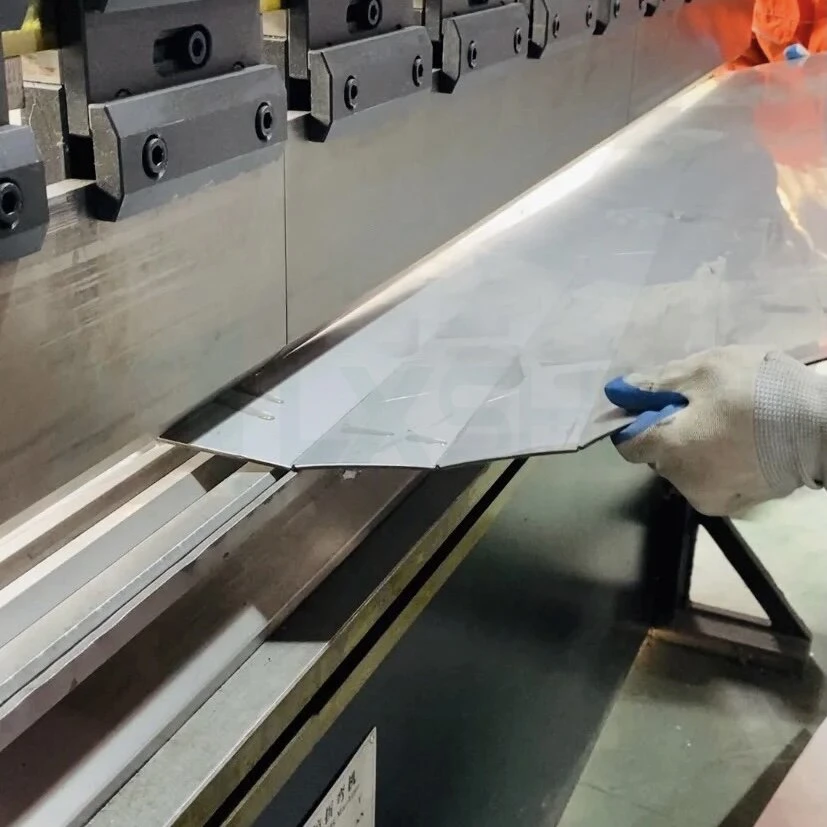

Sample Show

Factory

* About Jinan Lingxiu Laser Equipmentis established in July 2004, owns more than 500 square meters of researching and office space, more than 32000 square meters factory.All machines , passed the European Union CE authentication, American certificate and are certified to ISO 9001. Products are sold to USA,Canada, Australia, Europe, South east Asia,Africa etc,more than 150 countries and areas,and supply OEM service for more than 30 manufactures.

Customer Visit

FAQ

Q: Do you have CE document and other documents for customs clearance?

A: Yes, we have CE, Provide you with a one-stop service.

At first we will show you and and after shipment we will give you CE/Packing list/Commercial Invoice/ Sales contract for customs clearance.

A:Could you tell me your materials:cs or ss and their thickness? And the biggest bending width? Then i will confirm the machine model for you.

Q: How about warranty?

A: 3 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world, We need your machines running in order to keep your business running.

Q: Do you have any other machine style?

A: Yes, please check the following machine style, if you have any questions, you can contact us any time, 24x7, we always here.