Category

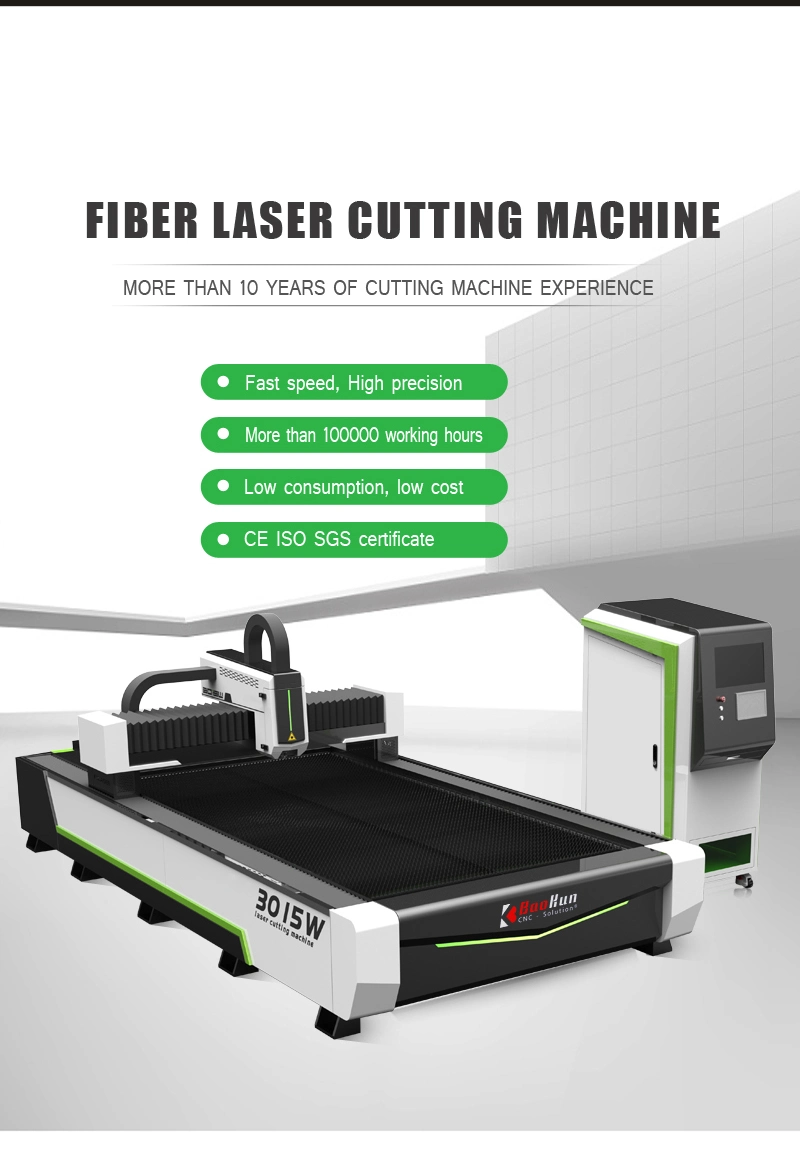

- Fiber Laser Cutting Machine

- 8Kw Laser Cutting Machine

- 1Kw Laser Cutting Machine

- 1.5Kw Laser Cutting Machine

- 2Kw Laser Cutting Machine

- 3KW Laser Cutting Machine

- Tube Laser Cutting Machine

- 9M Tube Laser Cutting Machines

- Coil Fed Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- 6Kw Laser Cutting Machine

- 12kw Laser Cutting Machine

- 15Kw Laser Cutting

- Press Braker

China Baokun Laser 4020 6020 6025 8025 Ipg Raycus 6kw 8kw 10kw 12kw CNC Fiber Laser Cutting Machine for Metal Sheet

China BAOKUN Laser 4020 6020 6025 8025 IPG Raycus 6kw 8KW 10KW 12KW CNC Fiber Laser Cutting Machine For Metal Sheet 1. H

Basic Info

| Model NO. | BAOKUN Fiber Laser Cutter |

| Application | Home Appliance, Aerospace Industry, Automotive Industry, Shoemaking Industry, Advertising Industry |

| Cooling System | Water Cooling |

| Technical Class | Continuous Wave Laser |

| Applicable Material | Metal |

| Structure Type | Gantry Type |

| Laser Classification | Solid Laser |

| Laser Technology | Fiber |

| Working Voltage | 380V 220V 3 Phase 50Hz/60Hz |

| Product Name | Baokun Fiber Laser Cutting Machine |

| Brand Name | Baokun |

| Key Selling Points | High-Accuracy |

| Cutting Materials | Metal |

| Driving and Motor | Servo Motor |

| Engraving Speed | 0-120000mm/Min |

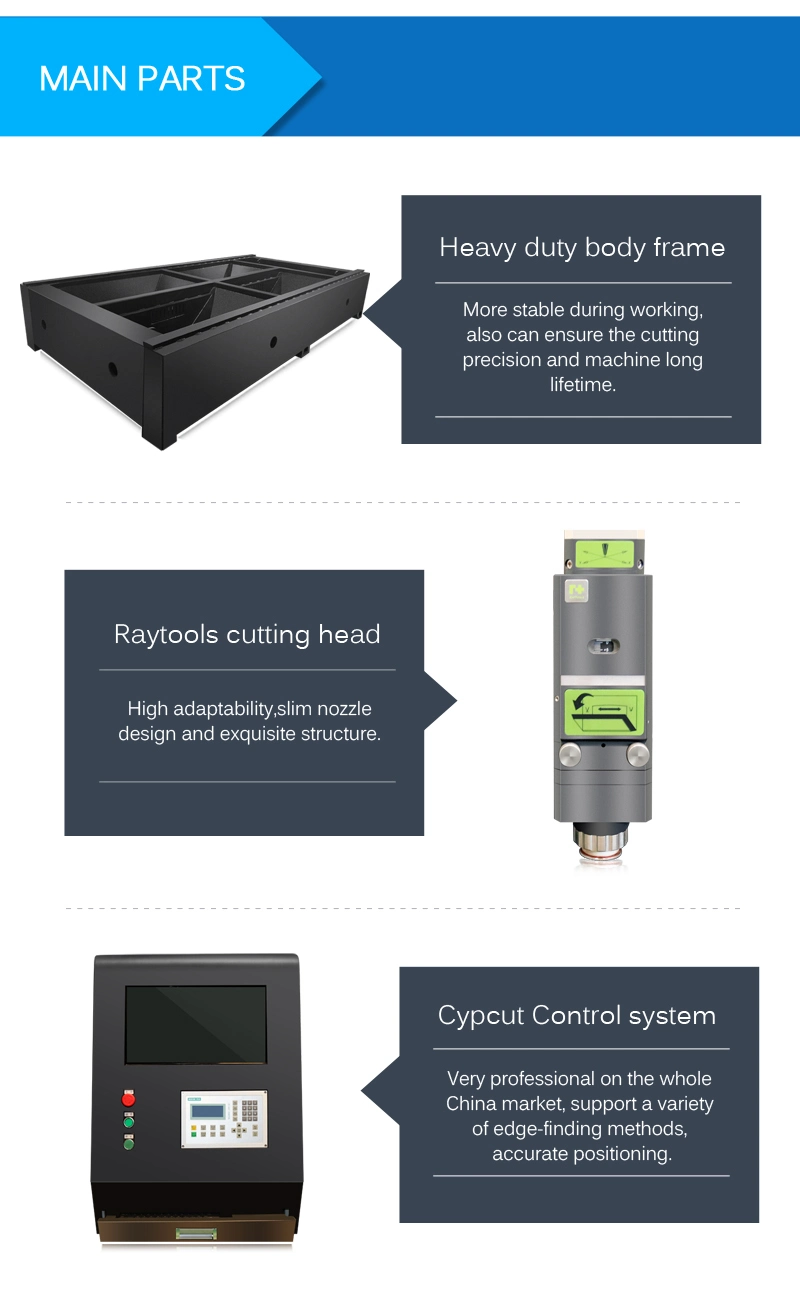

| Control Software | Cypcut |

| Laser Head | Raytools |

| Laser Source Brand | Raycus,Ipg,Reci |

| Warranty | 2 Years |

| Laser Power | 1000W / 2000W / 3000W/4000W |

| Transmission | Taiwan Yyc Gear Rack |

| Certificate | CE,ISO,SGS |

| Transport Package | Plywood |

| Specification | 1500mmx3000mm |

| Trademark | BAOKUN Fiber Laser Cutting Machine |

| Origin | Shandong, China |

| HS Code | 8456110090 |

| Production Capacity | 200 Sets Per Month |

Product Description

China BAOKUN Laser 4020 6020 6025 8025 IPG Raycus 6kw 8KW 10KW 12KW CNC Fiber Laser Cutting Machine For Metal Sheet

1. How can I choose a suitable fiber laser cutting machine?

Actually, more information be known will be more helpful to recommend. But there have some key points we must know, including:1.What materials do you need cut?2.What's the max size of the material?(Length *width* thickness)3.What are your functional requirements for the machine?4.If you have special requirements for machine parts, (such as power supply brand, motor driver or controller brand etc.) please let me know.

2. Do you have machine installation, debugging, training service?

Sure, we have.The fiber laser cutting machine was installed and debugged before delivery, you can use it directly after receiving.There also have English instruction book in the machine for your reference.Except, if you need, our engineer can arrive at your company to help to install and teach you how to use them more better, just some charge, and accommodation, tickets will be charged.

3. I am a fresher for this machine, is it easy to operate?

We help lots of freshers, if you have a reasonable knowledge of computers and willing to spend a little time learning it is not bad. And the English operating video and instruction book will sent to you free together with the machine.We also have 7X24 hours technical support by calling, video, IM and email.

4. If I need a not standard size machine, is it possible?

Sure! Our company have our own research and development department, own mature technology, can help customize machine according to your special requirements. Until now, we help to produce customized machines for more than 80 customers, and they said operate well.

5. Are there any machine in my country I can visit?

No problem ! We export machines all over the world, including America, Canada, Syria, Jordan, Pakistan,Surinam, Paraguay, Ecuador, Brazil, Guyana, Venezuela,Nicaragua,Taiwan New Zealand, Fiji, Australia, Sri Lanka, Malaysia, Philippines, Denmark, British, Germany, Italy, Spain, Portugal, Israel Libya, Saudi Arabia, Cote d'Ivoire, Nepal, Russia, Bulgaria, Iraq, Armenia etc., also have agent in America, Syria, Russia, will explore more and more.So if there is our machine in your country, we can contact the customer to arrange a visit for you.

6. How long does it take to make a machine ?

For general machine, it takes about 15 working days; for customized machine, generally is about 30 days. If have any special cases, will inform you advanced.

7. What's the purchase process for the fiber laser cutting machine?

Please tell me your detail requirements firstly, our sales representatives will recommend suitable machine and make a quotation for you. If have no any doubts, we will arrange to make machine after receiving your deposit.In this period, will let you know the production process. After everything finish, will offer machine pictures and videos for you to check.Then after receiving your balance payment, will arrange shipping for you.If you have any questions about operating machine, welcome contact our sales representatives 7X24 hours by email or calling.

If you have any other questions, welcome contact our professional sales representatives.

Application industry, mainly used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube fittings, automobile, food machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal foreign machining, kitchen utensils and appliances, and other manufacturing industries.

Applied materials: stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized board, aluminum-zinc plated board, pickling board, copper, silver, gold, titanium and other metal plates and pipe cutting.

Fiber Laser Cutting Machine Benefit!

Once a Fiber Laser has been used to cut, organisations will never revert back to traditional techniques. These are often much slower, involve costly tooling charges, can struggle to cut very thick materials and often entail lengthy process set-up times. Laser cutting processes also typically consume much less power than traditional cutting techniques and also waste much less material so could be a bona fide part of reducing an organisation's carbon footprint. The whole process is non-contact, which in itself has multiple benefits. These include reduced downtime and increased profits due to lower personal injury risk, no "wear and tear" of moving parts and no material damage due to contact.

| No. | Description | BKJ1530 |

| (Optional:BKJ2030,BKJ2040,BKJ2060) | ||

| 1 | Working Size | 3000X1500MM |

| (Optional: 2000x3000/2000x4000/6000x2000mm) | ||

| 2 | Laser Power | 1000/1500/2000/3000W |

| 3 | Cutting Thickness | 0.2-20mm |

| 4 | Cutting Speed | 1-150m |

| 5 | Cooling Way | Water Cooling |

| 6 | Processing Material | Stainless steel/carbon steel/galvanized steel/aluminum/copper/iron |

| 7 | Laser Head | Raytools |

| 8 | Laser Source | Raycus,GW,Reci,IPG |

| 9 | Rated voltage and frequency | 380V/50Hz/60Hz |

| 10 | Control System | Cypcut |

| 11 | Drive motor | Servo |

| 12 | Transmission system | Taiwan YYC gear rack |

| 13 | X.Y axis location accuracy | ±0.01mm |

| 14 | Transmit way | Taiwan imported TBI ball screw |

| 15 | Rail guide brand | Hiwin |

| 16 | Laser wave length | 1064nm |

| 17 | Operation language | English (Option) |

| 18 | Graphic format supported | CAD,DXF(etc) |

| 19 | Maximum acceleration | 1.5G |

| 20 | Spare parts | Electrode ,Electricity nozzle and Water chiller |

JUST CONTACT US NOW!HELP YOU CHOOSE A MOST SUTIABLE LASER CUTTING MACHINE!LET IT HELP YOU EARN MORE MONEY!!!!