Category

- Fiber Laser Cutting Machine

- 8Kw Laser Cutting Machine

- 1Kw Laser Cutting Machine

- 1.5Kw Laser Cutting Machine

- 2Kw Laser Cutting Machine

- 3KW Laser Cutting Machine

- Tube Laser Cutting Machine

- 9M Tube Laser Cutting Machines

- Coil Fed Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- 6Kw Laser Cutting Machine

- 12kw Laser Cutting Machine

- 15Kw Laser Cutting

- Press Braker

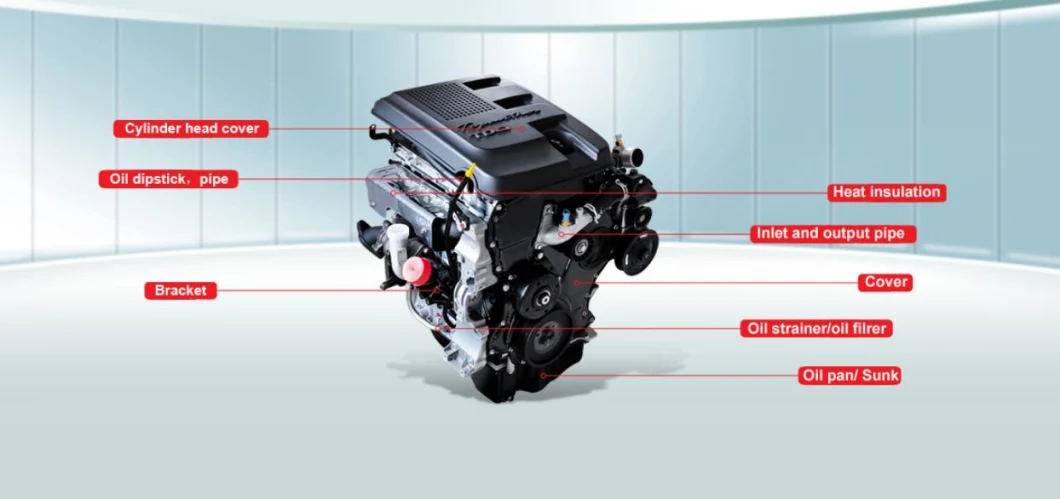

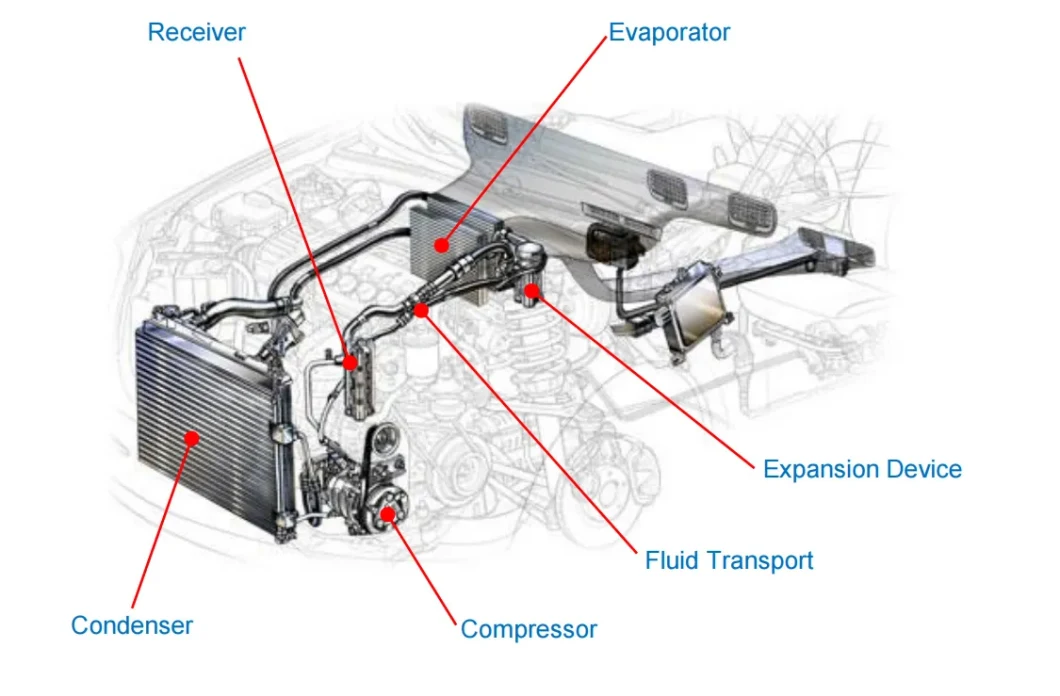

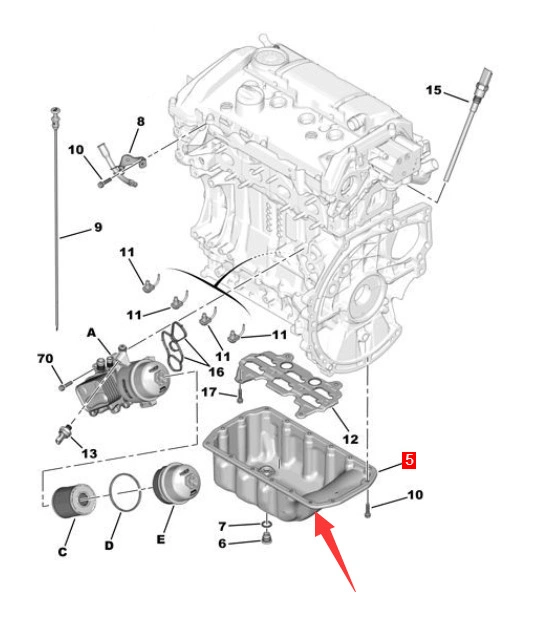

Car Accessories Engine-Cooling System

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stampin

Basic Info

| Model NO. | Non-standard parts |

| After-sales Service | Half Year |

| Warranty | One Year |

| Component | Coolant |

| Body Material | Iron |

| Cold Style | Water-cooled |

| Certification | ISO9001, TS16949 |

| Structure | Screw Type |

| Cooling Fluid Type | Glycol |

| Radiator Type | Cross-flow |

| Radiator Core Type | Pipe Belt |

| Water Temperature Sensor Type | Digital Type |

| Cooling Fluid Brand | Great Wall |

| Customized | by Drawing or Sample |

| Transport Package | Box |

| Specification | 120*45*32 |

| Trademark | MinZe |

| Origin | Quanzhou |

| Production Capacity | 10000000PCS/Year |

Product Description

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining.[1] This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined.Our advantages:30 Years OEM&ODM One-Stop Service in making various kinds of metal parts with a wide range from precision metal parts to large sheet metal stamping parts. According to customer's order quantity, we offer the most cost-effective way to your project, we can use laser cutting, single-shot or continuous progressive die automated production.we make various kinds of precision stamping parts in different material such as carbon steel, galvanized steel, stainless steel 304, 316, aluminum, copper, etc. We now have 100 customers from all over the world.1. We have own factory and 80% of staff in our company worked for more than 10 years.2. We provide a competitive price.3. High precision, tolerance can be within ±0.01mm.4. 14 years' export experience.5. Small order also is welcomed.6. We can also provide one-stop service, including mold and assembly.7. NDA apply to all customers.| Mold Material | DC01,DC04,DC06 |

| Tooling life Time | 100K times |

| Tooling Material | 1) AL1060, AL6061, AL6061, AL50522) Steel, mild steel, SPCC3) SS201, SS303, SS304, SS316, SS316L4) SPTE, galvanized sheet5) Brass, copper |

| Surface Treatment | Anodized, powder coating, lacquer coating, black oxide |

| Salt and spy test | From 72-480 h |

| Size | 1) According to customers' drawings2) According to customers' samples |

| Drawing Format | step, dwg, igs, pdf |

| Certificates | ISO 9001:2015 & IATF 16949 |

| Payment Term | T/T, L/C, Trade Assurance |

Production process

Customer at our work shop

Close deal at the meeting room

Delivery wheels to XiaMen dockWarehouse1.Do you provide samples ? is it free or extra ?Yes, we could offer the sample for free charge but do not pay the cost of freight.2. How about the shipping cost? The cost of shipping depends on the method you choose to obtain the goods. Express delivery is usually the fastest method, but it is also the most expensive method. Shipping is the best solution for large quantities. For the exact shipping cost, we can only provide you with detailed information after knowing the quantity, weight and dimension. 3. Do you have Stock productions to sell?Yes, of course. But we also offer OEM service. The mold is customized, Please send us some drawing.What information do you want to know if i want to get a quotation?a). The application for your products.b). Special package methods if you needs.4. Do you inspect the finished products?Yes. Each step of products will be carried out inspection by QC department until shipping5. How long is your delivery time?Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according toquantity.