Category

- Fiber Laser Cutting Machine

- 8Kw Laser Cutting Machine

- 1Kw Laser Cutting Machine

- 1.5Kw Laser Cutting Machine

- 2Kw Laser Cutting Machine

- 3KW Laser Cutting Machine

- Tube Laser Cutting Machine

- 9M Tube Laser Cutting Machines

- Coil Fed Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- 6Kw Laser Cutting Machine

- 12kw Laser Cutting Machine

- 15Kw Laser Cutting

- Press Braker

1000W 2000W 3000W 4000W 6kw 8kw Fiber Laser Cutting Machine for Metal Sheet Plate Stainless Carbon Steel Iron Aluminum

Overview Product Description Detailed Photos· Fiber Laser cutting machine · Cutting gold, silver, titanium, nickel, tin,

Basic Info

| Model NO. | ST3015 |

| Structure Type | Gantry Type |

| Laser Classification | Solid Laser |

| Laser Technology | Laser Fusion Cutting |

| Cutting Area | 3000*1500mm |

| Graphic Format Supported | Ai, Dxf, Plt, BMP, Dst, Dwg, Las, Dxp |

| Laser Source Brand | Raycus |

| Servo Motor Brand | Yaskawa |

| Control System Brand | Cypcut |

| Cutting Speed | 120m/Min |

| Cutting Thickness | 6mm |

| Control Software | Cypcut |

| Laser Head Brand | Raytools |

| Guiderail Brand | Hiwin |

| Weight (Kg) | 3000 Kg |

| Core Components | Laser Source |

| Products Handled | Sheet Metal |

| Mode of Operation | Continuous Wave |

| CNC or Not | Yes |

| Transport Package | Standard Wooden Case |

| Trademark | MORITA |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 2000PCS/Year |

Product Description

| Model | 3015F |

| Laser wave length | 1064nm |

| Transmission system | Gear + rails(we have standard brand, we can also produce as your requirements) |

| X.Y axis location accuracy | ±0.01mm |

| X.Y axis repeat location accuracy | ±0.01mm |

| X.Y axis max moving speed | 120m/min |

| Application Material | plate /sheet metalwork;Iron / Carbon Steel / Stainless Steel / Aluminum/ Copper and all kinds metal |

Standard:

Stable Lathe* Plate welding bed, more stable and durable.

* After annealing treatment, the bed ensures the smooth operation of the cutting machine.Laser Source

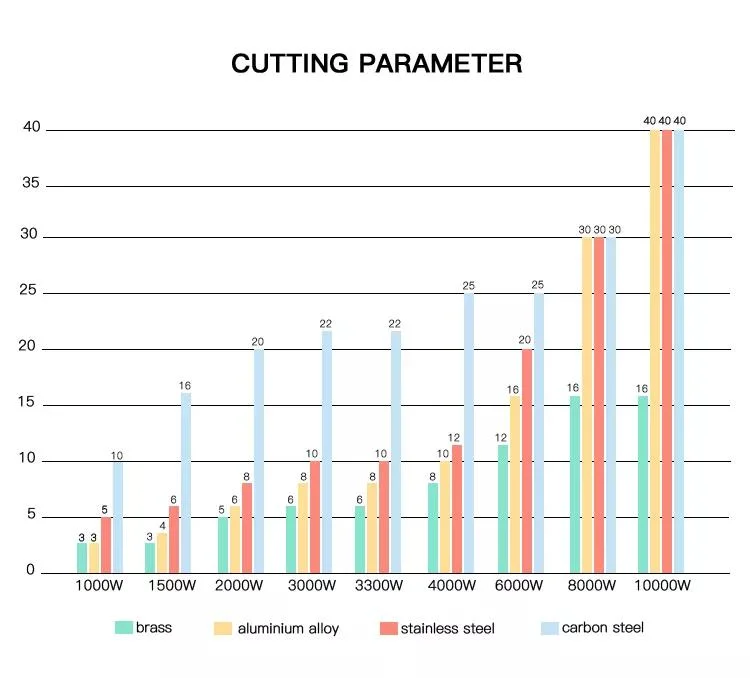

* High power, from 1000W to 15000W.

* Raycus/MAX/IPG, multiple choice different brands, different laser power are available. * The higher power, the thicker cutting thickness.Automatic Focusing Laser Head

* Raytools, Au3tech, WSX can be selected, high speed and stable. * Laser head follow-up funtion Follow the change of the height of the board.Servo Motor And Drives

You can choose YASKAWA/FUJI.* Accuracy: realizes closed-loop control of position, speed and torque; overcomes the problem of stepping motor out of step;

* Rotating speed: high speed performance, general rated speed can reach 2000~3000 rpm.Cypcut Plane Control System(2000)

* CypCut plane cutting software is a set of software specially developed for the deep customization of the laser cuttingindustry. Easy to use, rich in functions, suitable for various processing occasions.* Edge finding aid Dual-drive deviation self-correcting two-stage capacitive edge seeking.

Fiber Laser Cutting Machine

From CustomersCompany Profile· With 15 years experience, MORITA LASER has established a complete system for the development and manufacture of laser marking, cutting, engraving and welding technologies.

· Main products: fiber laser cutting machine, fiber laser marking machine, crystal engraving machine, CO2 laser marking machine, UV laser marking machine, laser engraving machine, laser cutting machine, CNC engraving machine, CNC processing center, stone engraving machine and other products.

As a responsible company, we are dedicated to develop new techniques out of concern of environmental protection. Disposable products are the first priority. In the near future, we will launch more and more environmental friendly products.

FAQQ1 :Our workers can't operate the machine, how to train the staff?A1:We will send you the teaching video of the machine and 24-hour online service,we also support free training service, engineers can train your workers for free in our factory for 1-3 days,if you want door-to-door service,We can arrange local service in 48 hours.Q2 : I don't know which one is suitable for me ?A2:Please tell me your:1) Your materials2) Max size of your material3) Max cut thickness4) Popular cut thicknessQ3 :It's not convenient for me to go to China, but I want to see the condition of the machine in the factory. What should I do?A3:We support the production visualization service. The sales department who responds to your inquiry for the first time will be responsible for your follow-up work. You can contact him /her to go to the factory to check the production progress of the machine, or send you the sample pictures and videos you want. We support free sample service.Q4: I don't know how to use after I receive Or I have problem during use,how to do?A4: 1) We have detailed user manual with pictures and CD,you can learn step by step.And our user manual update every month for your easy learning if there is any update on machine.2) If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/Whatsapp/Email/Phone/Skype with cam till all of your problems finished.We can also provide Door service if you need.