- Fiber Laser Cutting Machine

- 8Kw Laser Cutting Machine

- 1Kw Laser Cutting Machine

- 1.5Kw Laser Cutting Machine

- 2Kw Laser Cutting Machine

- 3KW Laser Cutting Machine

- Tube Laser Cutting Machine

- 9M Tube Laser Cutting Machines

- Coil Fed Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- 6Kw Laser Cutting Machine

- 12kw Laser Cutting Machine

- 15Kw Laser Cutting

- Press Braker

50W 100W 200W Mopa Rust Removal Backpack Pulse Laser Cleaning Machine for Paint Removal

Basic Info

| Model NO. | DV-LCB |

| Laser Type | Pulse Laser |

| Cable Length | 3m |

| Cooling Mode | Air Cooling Cooled |

| Power Supply | 220V, 50Hz/220V, 60Hz |

| Application | Metal Surface Treatment, Moulds Repair |

| Advantage | Non Damage to Workpiece Surface; Precise Scanning |

| Laser Source | Max Mopa; Jpt Mopa |

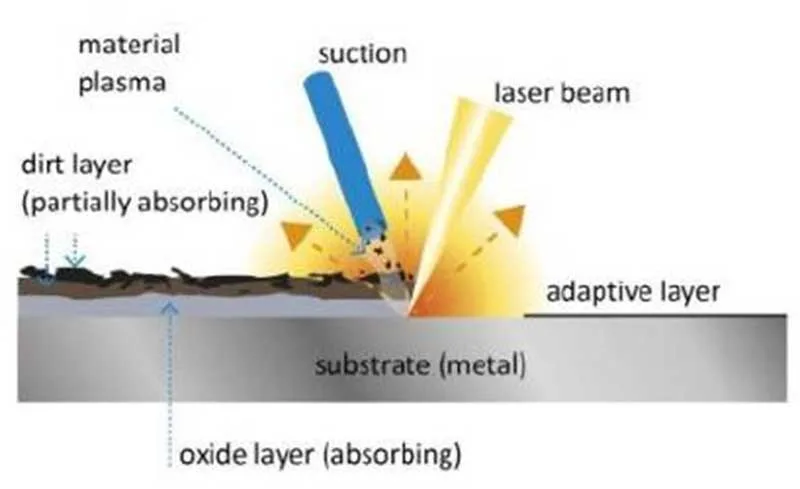

| Cleaning Item | Rust, Paint, Oxide Layer, Tar, Puty, Oil, Wood |

| Manufacturing Place | Shandong Jinan |

| Machine Type | Handheld Type |

| Selling Point | Portable and Small |

| Weight | 12kg |

| Business Type | Manufacturer Factory |

| Transport Package | Wooden Box |

| Specification | 1CBM |

| Trademark | D. Ventus |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 50 Sets Per Month |

Product Description

50W 100W 200W Mopa Rust Removal Backpack Pulse Laser cleaning machine for Paint Removal

Features:

** Non-contact cleaning without damaging the matrix of the parts;

** Accurate cleaning, which can achieve precise position, accurate size selective cleaning;

** Do not need any chemical cleaning liquid, no consumables, safety and environmental protection;

** Simple operation;

** Ergonomics design;

** High cleaning efficiency, which can largely save time cost;

** Stable cleaning system with little maintenance.

Specification of Pulse Laser Cleaner:

Operating Environment | |

Model | DV-LCB |

Supply voltage | Optional single battery, 100W continuous work 80-90min |

Standard AC220V±10%, 50/60Hz power adapter (output DC48V) | |

Power consumption | ≤300W |

Working environment temperature | 5ºC~40ºC |

Working environment humidity | ≤80% |

Optical Parameters | |

Average laser power | ≥100W |

Power instability | <5% |

Laser Working Mode | Pulse |

Pulse width | 150-190ns |

Maximum monopulse energy | 1.7mJ |

Power regulation range(%) | 0-100( Gradient Adjustable) |

Repeat frequency(kHz) | 20-200(Gradient Adjustable) |

Fiber length | 1.5m |

Cooling mode | Air cooling |

Cleaning Head Parameters | |

Scan range (length * width) | 0mm~100 mm, continuously adjustable;Biaxial supporting 8 scanning modes |

Scanning frequency | 10Hz~300Hz Continuous Adjustable |

Field mirror focal length(mm) | 160mm( Optional 210mm/254mm/330mm/420mm) |

Depth of focus | About 5 mm |

Mechanical Parameters | |

Machine size(Length, width and height) | About330mm×123mm×380mm(Excluding battery) |

About330mm×168mm×380mm(Including battery) | |

Machine Weight | About 8.5 Kg(Excluding battery) |

About 13Kg(Including battery) | |

Cleaning head weight (including isolator) | <0.8kg |

Mode of operation | Handheld/automated |

Machine Details of Laser Cleaning Machine:

Advantages :

1) High cleanliness and precise positioning cleaning;2) Non-contact cleaning, protecting brittleness material surface;3) Zero maintenance cost and environmental friendly;No chemical pollution, no noise, energy-saving;4) It can clear the pollution particles below the nanometer level and have high cleanliness;5) Fiber optic transmission can move operation, can clean the area which is not easy to reach;6) Laser cleaning can solve the problems that traditional cleaning methods can not solve with high efficiency and powerful capacity;7) With wide materials application scope.

Applications of Laser Cleaner Machine:

1) Metal surface derusting2) Surface paint removal paint treatment3) Surface without dirt, stains, dirt cleaning4) Surface coating, coating removal5) Oxide surface,Oil stain and contaminant cleaning6) Welding surface / spray surface pretreatment7) Stone figure surface dust & attachment cleaning.8) Rubber/ plastic/ metal mold residue cleaning

Applied Industries:

Reliable Services:

1. All of machines are fully assembled and thoroughly tested and checked prior to shipment.2. We provide pre-sales technical advisory services, technical maintenance training and operational training services.3. We provide free repair for main spare parts within warranty period according to warranty agreement.4. We provide upgrades and maintenance for software system within warranty period.5. We provide technical maintenance and repair for third-party hardware and software products according to third-party manufacturer's warranty-grade.6. We provide preferential lifetime maintenance of all equipment, spare parts are charged according to the prevailing market price beyond warranty period.